EATON — Local manufacturer Bullen Ultrasonics announced last week that it will be remaining open during the COVID-19 pandemic.

Bullen manufactures key parts for various medical devices that are in high demand as the coronavirus spreads across the U.S., according to Bullen President Tim Beatty.

“We understand that COVID-19 is quickly creating a dramatic shortage of ventilators in our nation,” Beatty said. “That is why we’re committed to following the governor’s employee safety mandates while continuing to do our part for the greater good.”

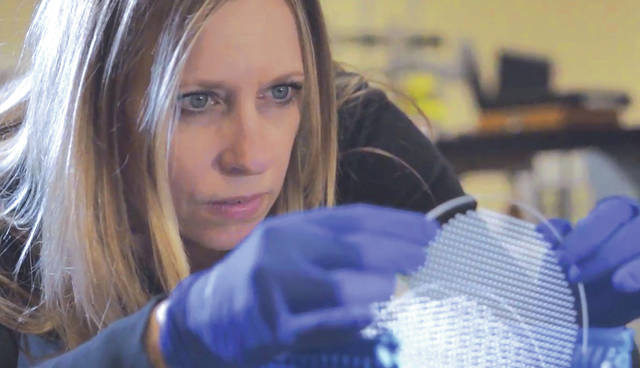

Bullen provides a key component for the sensors found in ventilators. These sensors are necessary for measuring the air and oxygen pressure going to and from a patient. The ventilators are used to treat patients suffering from shortness of breath, one of the more commonly publicized symptoms associated with the coronavirus.

Bullen also supplies parts to other businesses considered “essential,” according to Beatty, including Department of Defense contractors and aircraft manufacturers.

“We’ve not only learned that we’re essential and can’t close down, but that it’s actually of global importance that we stay open,” Beatty said.

Beatty stressed that the safety and comfort of Bullen’s employees is important to the company as well, however, and that various measures have been taken to try and ensure that Bullen’s workers stay healthy.

“The nature of our work has always driven us to maintain a healthy and clean facility, and we are currently enforcing extra measures in light of the pandemic to further prioritize our employees’ health and well-being,” Beatty said.

These measures include setting up temperature checks for each employee as they report to work, according to Beatty. In addition, the company has invested in a new touchless clock-in system that allows employees to clock in using their smartphones, and is also thoroughly sanitizing all work and public spaces twice per shift.

“We’re thinking about high-touch areas: doorknobs, machine controls, coffee pots,” Beatty said. “We have leads in each department who are responsible for wiping everything down.”

Bullen has a total of 139 employees, about a quarter of whom are capable of working from home, according to Beatty. In addition, Bullen’s second and third-shift teams include only about 20 employees, Beatty said, while the first-shift staff of around 100 workers has been cut by about a third. All of this helps Bullen’s workers to maintain proper social distancing.

“It hasn’t been terribly challenging, given that our operations are already pretty spread out,” Beatty said. “We’ve also been putting people on rotation so we have all the critical people we need here and others can stay at home.”

All of this has been done without having to affect anyone’s compensation, according to Beatty, though employees who aren’t comfortable coming in and are unable to work from home have also been given the option to take paid or unpaid leave during the crisis.

“We’ll do that until we feel our employees are safe to come back,” Beatty said.

Beatty stressed that Bullen’s employee safety procedures go above and beyond what’s been recommended by Governor Mike DeWine and others.

“We see those as bottom-level requirements, and we want to do more if we can,” Beatty said.

“What’s interesting about all this is that we’ve redefined what we mean by ‘hero,’” Beatty said. “A hero used to be an athlete or a movie star. But our heroes today are healthcare workers, delivery people, cashiers. And I think it’s people like we have here, who are making these parts. So we’re proud to be a part of that.”